Parts fabrication, Assembly, and Packaging of a complete device are the final steps in the product development journey.

MaNUFACTURING

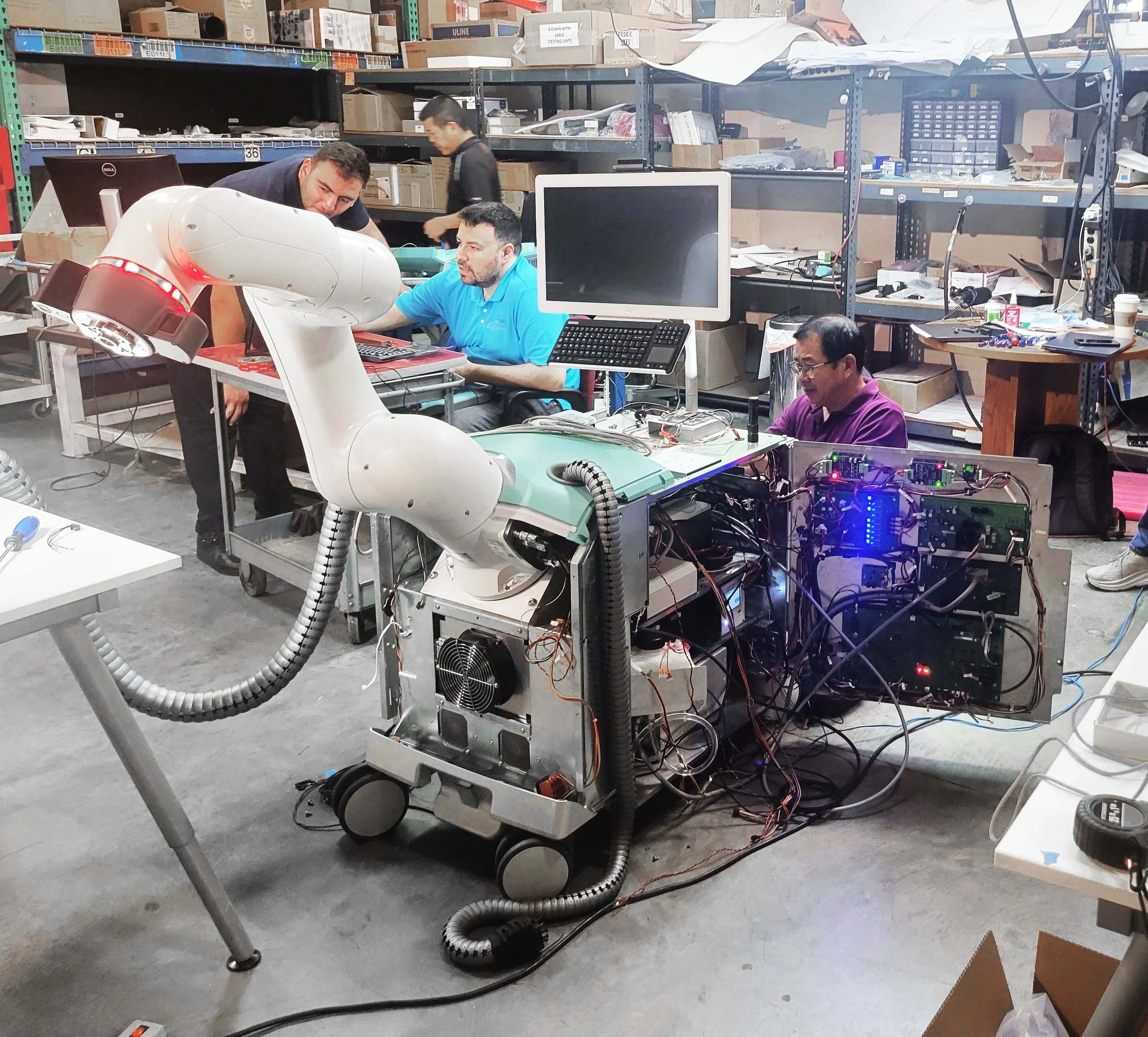

SYSTEM INTEGRATION

Combining hardware, software, and electronics into a single, functioning product. We ensure all components work together reliably, meet requirements, and perform as intended for real-world use.

COMPONENT ASSEMBLY

Bringing together individual parts into a complete, functional product with accuracy and repeatability. Overseeing proper fit, structural integrity, and efficient manufacturing while supporting product performance and quality.

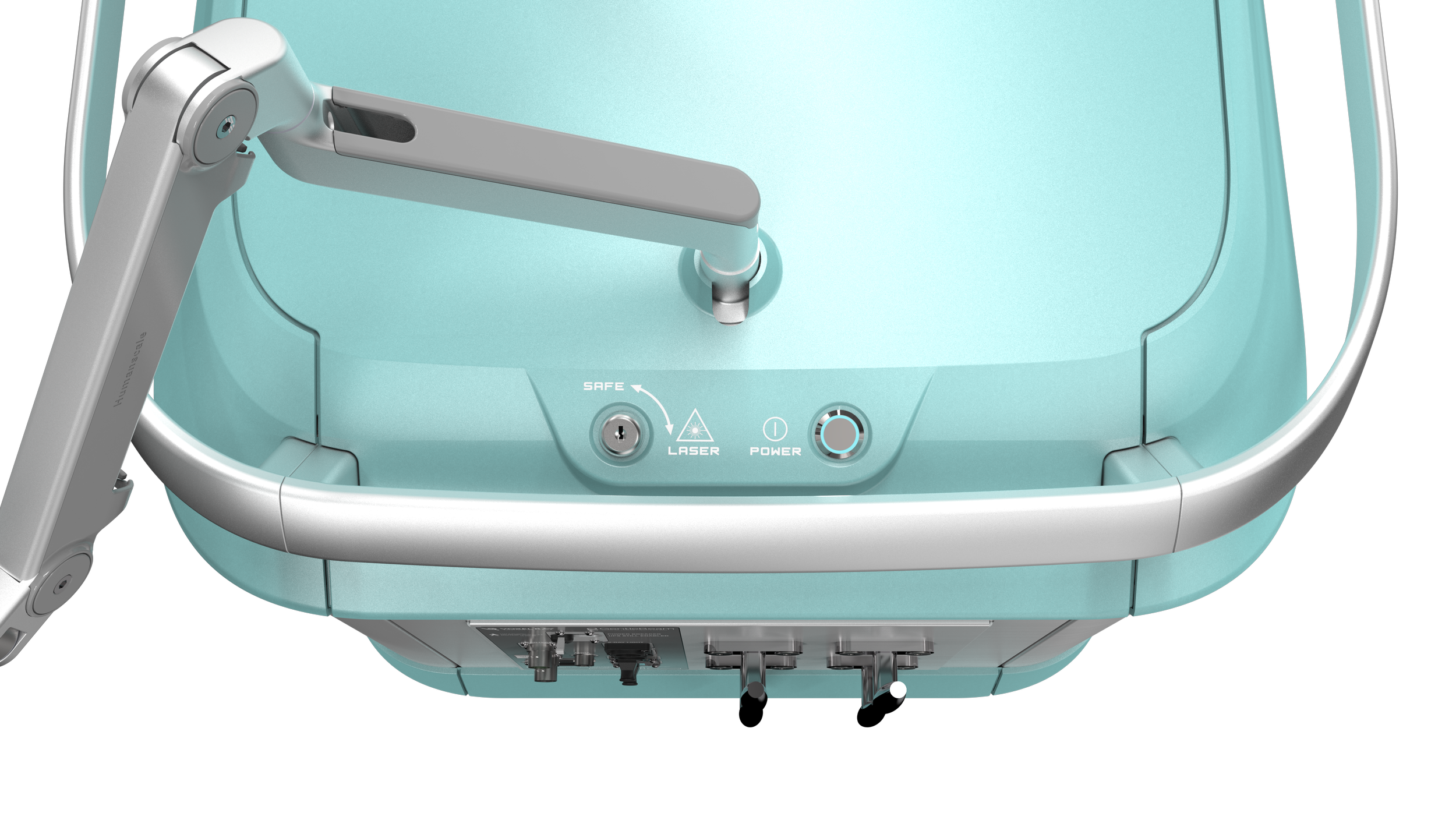

TRADE SHOW READY

Design is refined into a polished, fully assembled prototype ready for presentation and live demonstrations. Helps drive meaningful conversation with potential customers and investors.

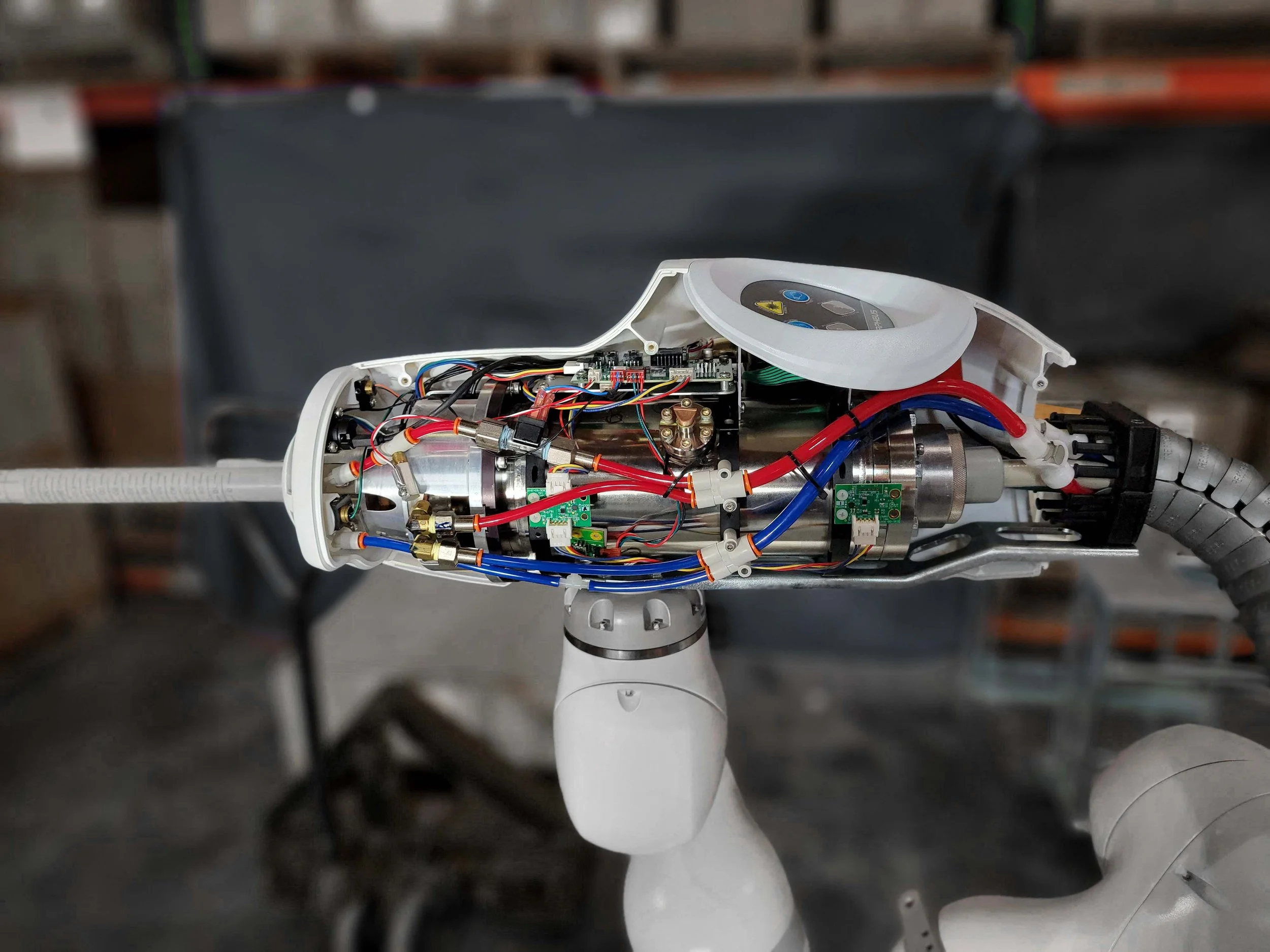

ASSEMBLY

We offer in-house assembly capabilities for complete product builds. This allows you to maintain direct control over quality, fit, and performance throughout the build process. Faster iteration, tighter coordination between design and engineering, and reduced reliance on external manufacturing partners.

PRODUCT TESTING

We are able to evaluate performance, usability, and reliability throughout development. It enables faster feedback, reduced risk, and more informed design decisions before moving to production.

IN-USE

The finished product is ready to be used for it’s intended purposes with full confidence and reliability.

USER testing

The prototyping phase yields production quality units that are ready for users to test and document their user experience.

USER EXPERIENCE

User feedback is used to refine the products so that the production units are optimized and fully vetted out.

Hardware-Software Integration

Firmware and/or software integration provides an intuitive user experience.